Pulverizer Grinding Elements Analyzer

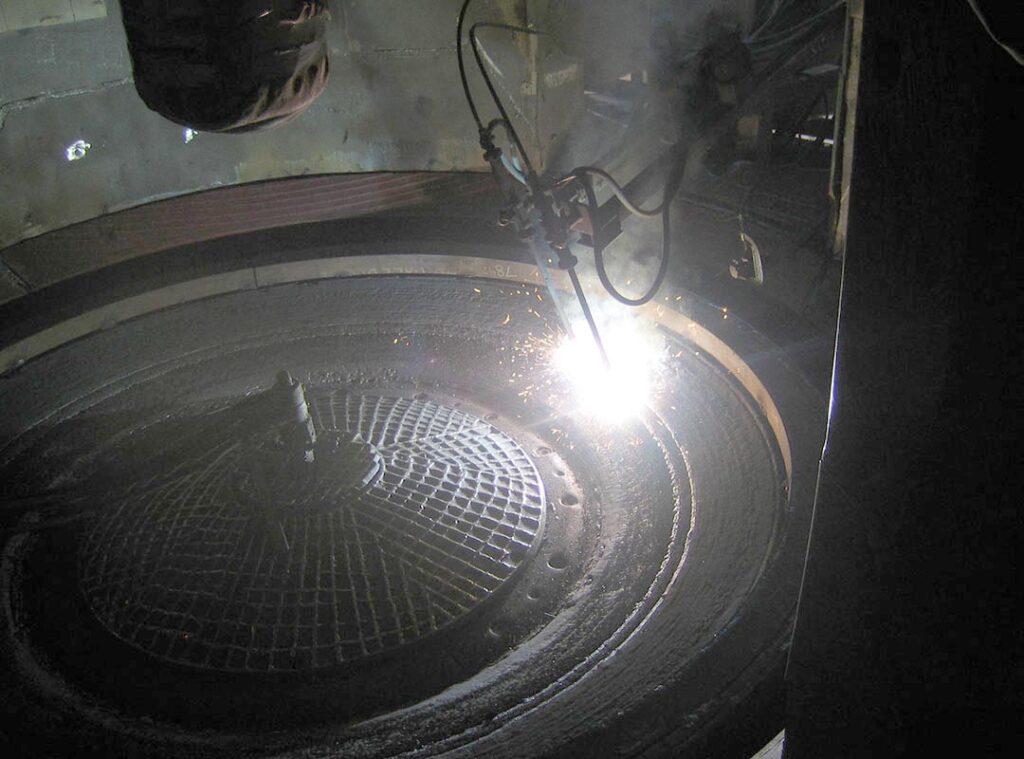

Roll-Bowl COP

Pulverizer issues are the leading cause of partial forced outages for coal fired generating units. RBC analyzes grinding elements to determine wear and structural integrity of the equipment.

Enhance Pulverizer Performance

Prevent Forced Outages with RBC’s Grinding Elements Analysis for Reliable Pulverizer Performance

Monitoring and Diagnostics

- Improve Pulverizer Performance Continuous monitoring ensures proper adjustment and uniform contributions from each of the grinding elements.

- Reduce Coal Mill Maintenance Maximize mill life and extend overhaul intervals.

- Maximize Boiler Performance By ensuring proper granularity of the mill output, NOx and slagging potential are significantly lowered.

- Tried and True Non-Invasive Testing Methods with proven results.

- Portable and On-line Systems Portable system that can be easily moved and a more permanent Online system for long term monitoring.

Monitoring and Diagnostics

Data Collection

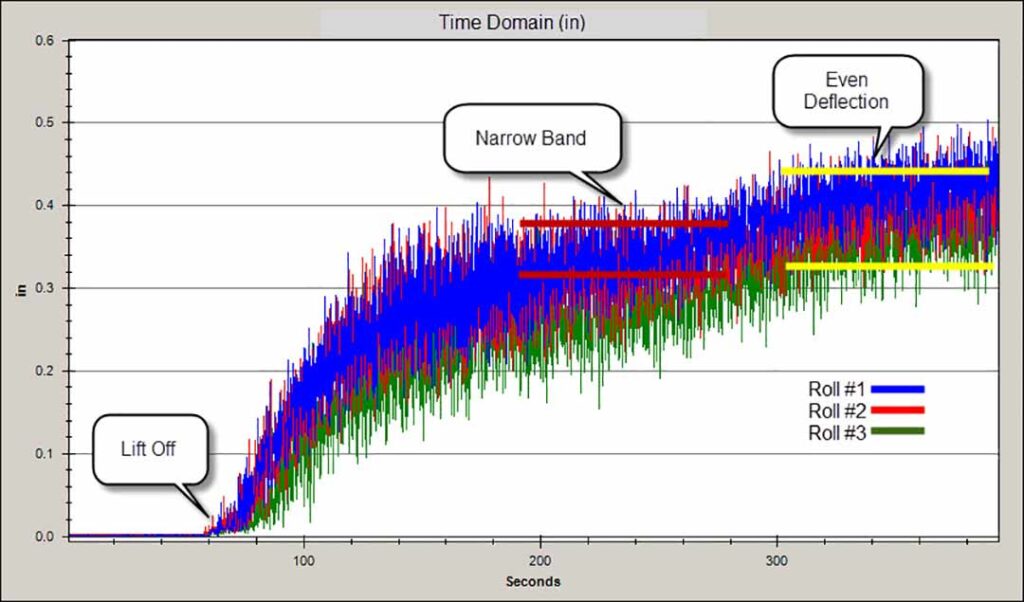

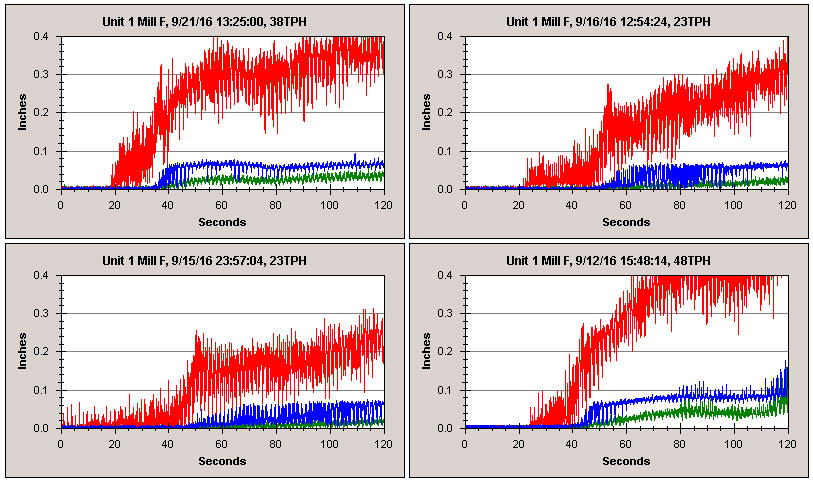

The Roll-Bowl COP system contains the software and hardware necessary to collect and analyze coal pulverizer operating data, using both time-domain and frequency domain techniques, to reveal the dynamic conditions present within the mill without removing it from service.

Proprietary Analysis Techniques

Roll-Bowl COP is a patented technique that is used to monitor and improve the performance of coal pulverizers. RBC provides non-intrusive, dynamic analysis of the grinding elements, bearings and gearbox.

Proper Mill Adjustment

The results of this analysis are used to optimize the settings and adjustments of the mill and assure the accurate assembly of the grinding elements.

Compatible with PI

Data is written to the Aveva® PI System®. Fifty variables stored for each mill.

Optimize Mill Performance

Data Acquisition

System utilizes dedicated instruments and high speed data acquisition to collect and analyze mill operating variables.

APR-Based Diagnostics and Detection

Predictive Analytics techniques are used with existing process instrumentation to characterize normal operation and detect anomalies. The system can detect:

- Collapsed or broken spring

- Improperly adjusted rolls

- Spalled material from roll or table

- Excessive wear

- Vertical shaft and roll bearings and drive train issues

- Unbalanced table loading

Data Visualization

Provides visualization of potential issues with grinding issues not observable from outside the mill or by any other process data.

Maximize Mill Life

Reduces fatigue loading on vertical shaft, monitors spring anomalies, wear, and component geometry.

Optimize Pulverizer-Related Boiler Impacts

Optimized mill operation will have a cascaded effect on the boiler, improving combustion, LOI, NOx, slagging, and partial derates.

Mill Monitoring Options

Portable Mill Testing System

- Non-intrusive, external testing

- Dynamic analysis of grinding elements

- Quick and easy setup and user-friendly data collection

- Web-based data analysis tools

- Snapshot data of current performance and setup

Online Mill Monitoring System

- Same grinding elements information as portable system

- Continuous monitoring of mill performance

- Immediate detection of mill events

- Added vibration data collection on mill components, gear box, and motor

- Data written to Aveva PI System

Product Video

Product Support

Access guides, manuals, software downloads, training videos, and more in our product support center.